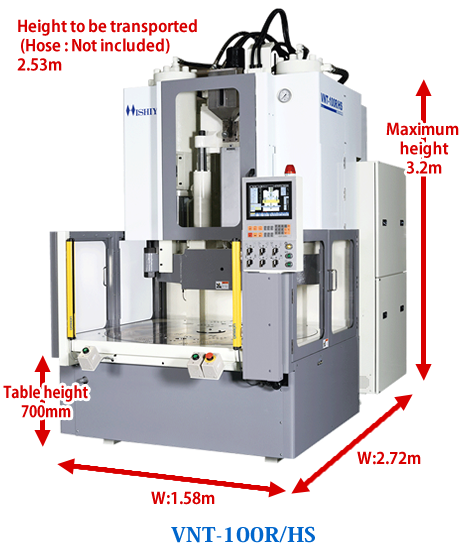

VNT-30R・VNT-70R SSH・VNT-100R/HS

As the table position is approximately 70cm from the step, work efficiency improves.!

With its compact size, there is no need to select space to put the fixed area.

Easy to adapt to freely molding design due to the tiebar less concept! By making sure of wide operation space,it's further efficient at the work.

The vertical type injection molding machine which will pioneer the 21st century

The vertical injection molding machines with our technology and results have a history of about 60 years, adapting an unique idea for new machine series.

The tie bar less formulated vertical injection moling machine is appeared!

By using an insert hoop molding method, the working efficiency can be improved.

Vertical injection molding machine VNT-100R/HS Removal of purge material

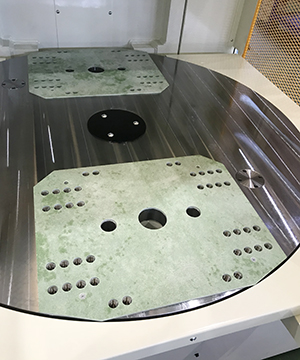

Vertical injection molding machine VNT-100R/HS Turntable

The following info. can be downloaded by PDF.

The following info. can be downloaded by PDF.

The following info. can be downloaded by PDF.

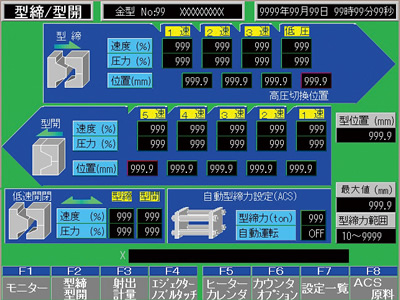

Not only 3 gradation of mold clamp plus low pressure, but also 5 gradation of speed and pressure control brings smoother clmping.

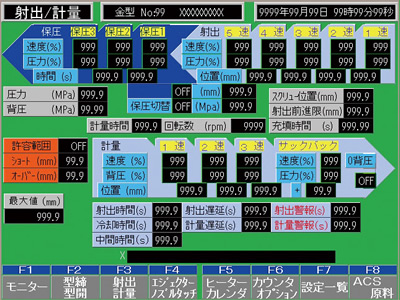

5 gradation of injection speed control 3 gradatiion of hold pressure control plus charging speed and back prssure of 3 gradation are controlled. ( 3 gradation of back pressure is available as an option.) High molding precision is attained.

Weekly calendar timer is equipped. By adapting PID control and SSR circuit, we promise extremely precise control.

1500 shots of molding condition data are retro-spectively able to be monitored. Highly precise quality control and observation of poor results are securely feasible.

AREA SENSOR

FALL PRVENTION LEVER

LEVEL PAD

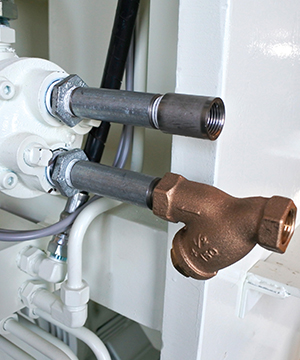

MOLD COOLING UNIT

MOLD CLAMP

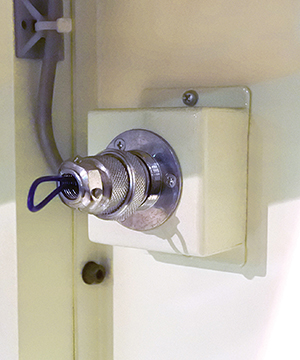

IN TAKE PIPE OF OIL COOLER

HEAT NSULATING PLATE

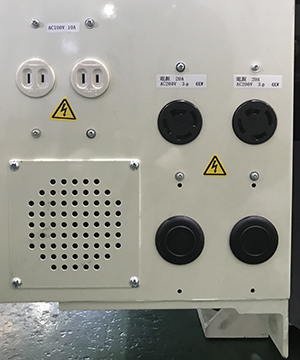

SPARE ELECTRICAL SOCKET

SPARE PLUG

METAL PLUG FOR INTERLOCK

SPRING TYPE BALL BEARING