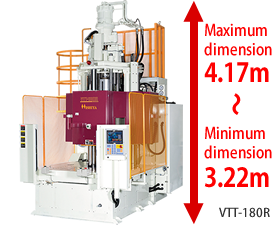

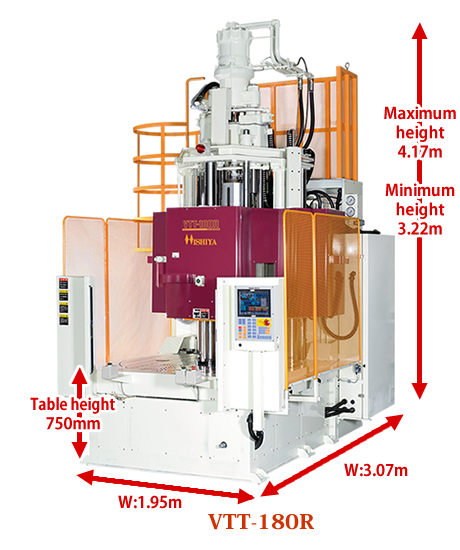

VTT-180R・VTT-260R

As the table position is about 75cm from the step, work efficiency improves.!

With its compact size, there is no need to select space to put the fixed area.

When carrying, the machine can be disassembled up to 2.82m. ( Please ask our sales dept.)

The vertical type injection molding machine which will pioneer the 21st century

Compact & high efficiency. High energy-saving variable pump equipment. New series!

Greatly low! Pay attention to the surprising small fixed area.

VTT-180R Hopper Entrance

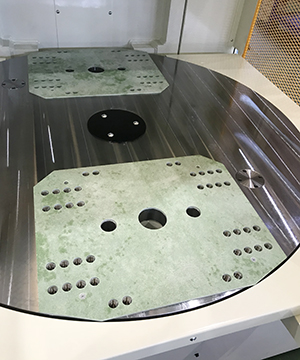

Vertical Injection Molding Machine VTT-180R Rotary table

The following info. can be downloaded by PDF.

The following info. can be downloaded by PDF.

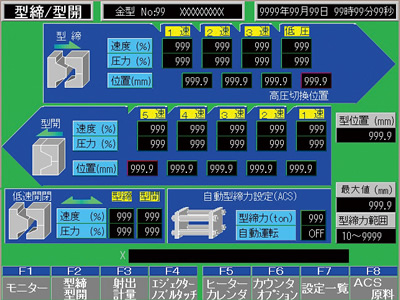

Not only 3 gradation of mold clamp plus low pressure, but also 5 gradation of speed and pressure control brings smoother clmping.

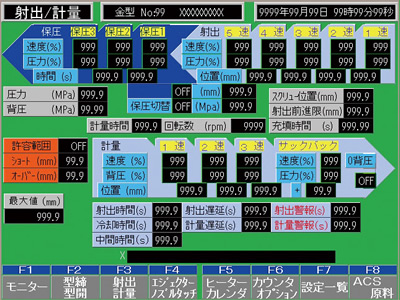

5 gradation of injection speed control 3 gradatiion of hold pressure control plus charging speed and back prssure of 3 gradation are controlled. ( 3 gradation of back pressure is available as an option.) High molding precision is attained.

Weekly calendar timer is equipped. By adapting PID control and SSR circuit, we promise extremely precise control.

1500 shots of molding condition data are retro-spectively able to be monitored. Highly precise quality control and observation of poor results are securely feasible.

AREA SENSOR

FALL PRVENTION LEVER

LEVEL PAD

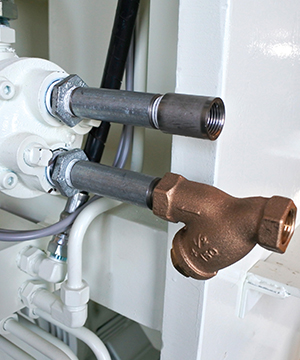

MOLD COOLING UNIT

MOLD CLAMP

IN TAKE PIPE OF OIL COOLER

HEAT NSULATING PLATE

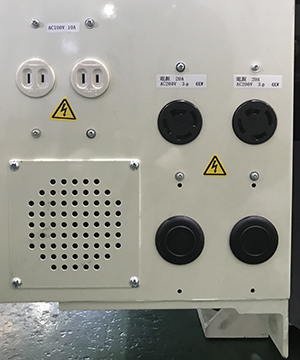

SPARE ELECTRICAL SOCKET

SPARE PLUG

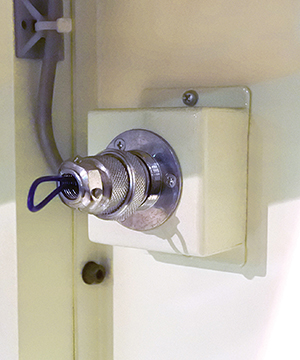

METAL PLUG FOR INTERLOCK

SPRING TYPE BALL BEARING